Project Overview

On a CANDU reactor the calandria relief ducts allow the calandria to be vented if they reach an over pressure condition and enable the circulation of inert helium to mitigate the risk of a hydrogen explosion. Access to these ducts is restricted and they include many internal bands.

At Bruce Power unit 7 it was found that the ducts had been degraded due to transgranular chloride induced stress corrosion cracking. Specialized tooling was required both inspect and clean the relief ducts in order to allow for safe continued operation.

How We Helped

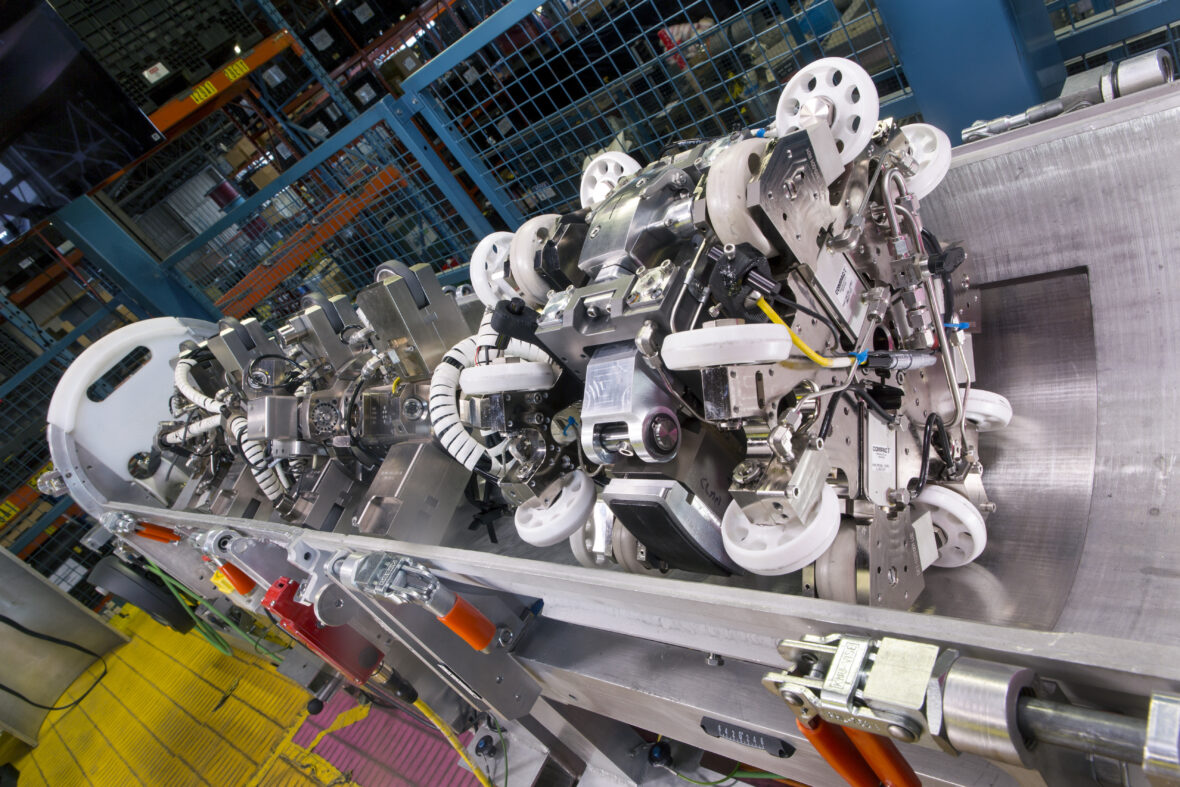

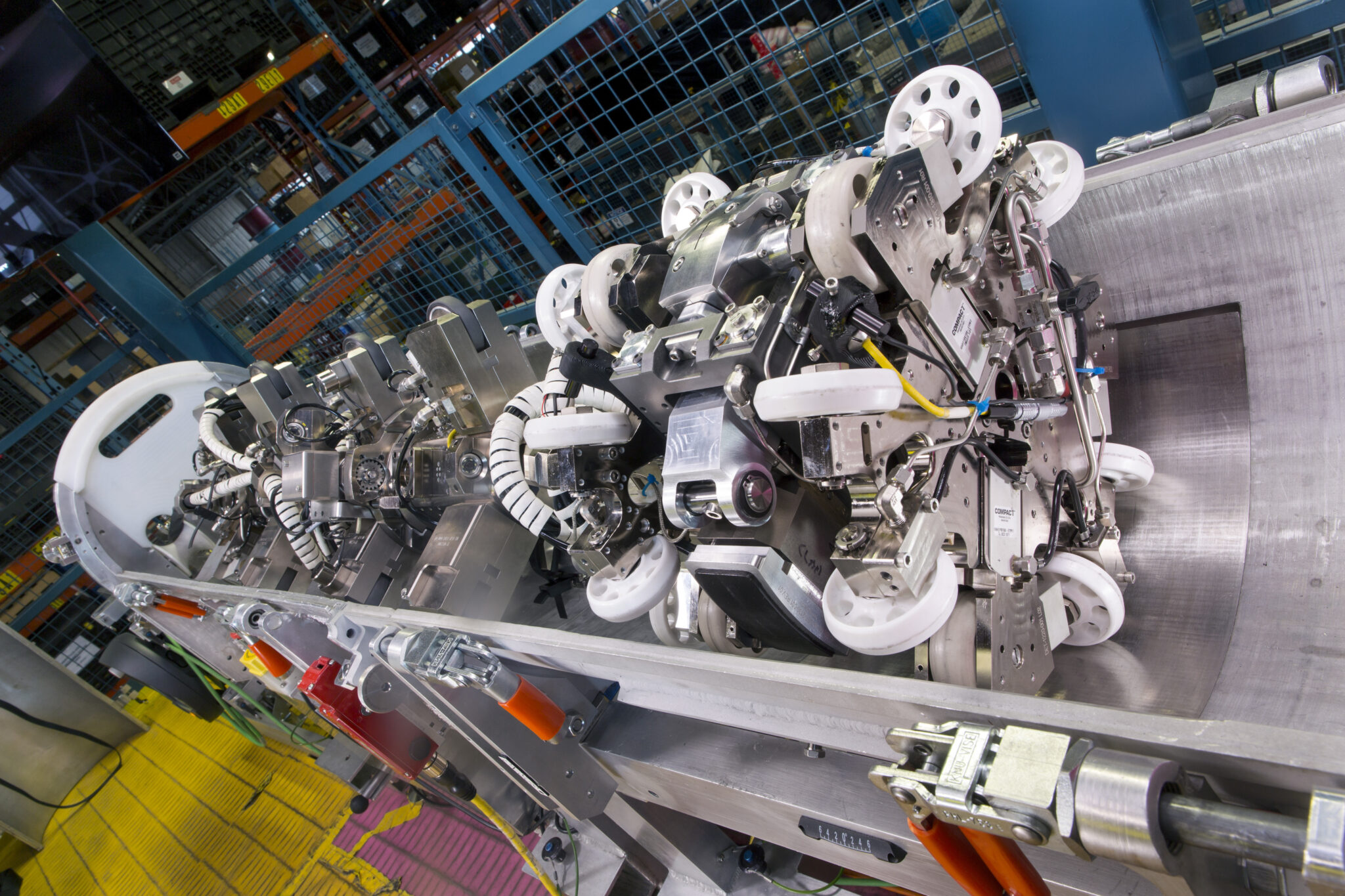

We designed a first-of-a-kind tool which is regarded as one of the most complex in the nuclear industry.

We were able to leverage OPEX from past CRD inspections to develop a tool which was not only successfully deployed for multiple outages (B1671, B1971, B2171), but also incorporated improved tooling design and operation.

The improvements reduced outage critical path by eight days, in addition to improved inspection data quality of the CRDs. We utilized new, innovative means to design and improve the CRD inspection tooling such as the use of a mock-up and training facility at the Kipling facility (see leftmost photo). The successful deployment of this tool for NDE of all four CRDs allowed for Bruce Power to make an informed decision to continue operating Unit 7 in light of the life-limiting conditions posed by the CRDs.