Pressure Systems Overview

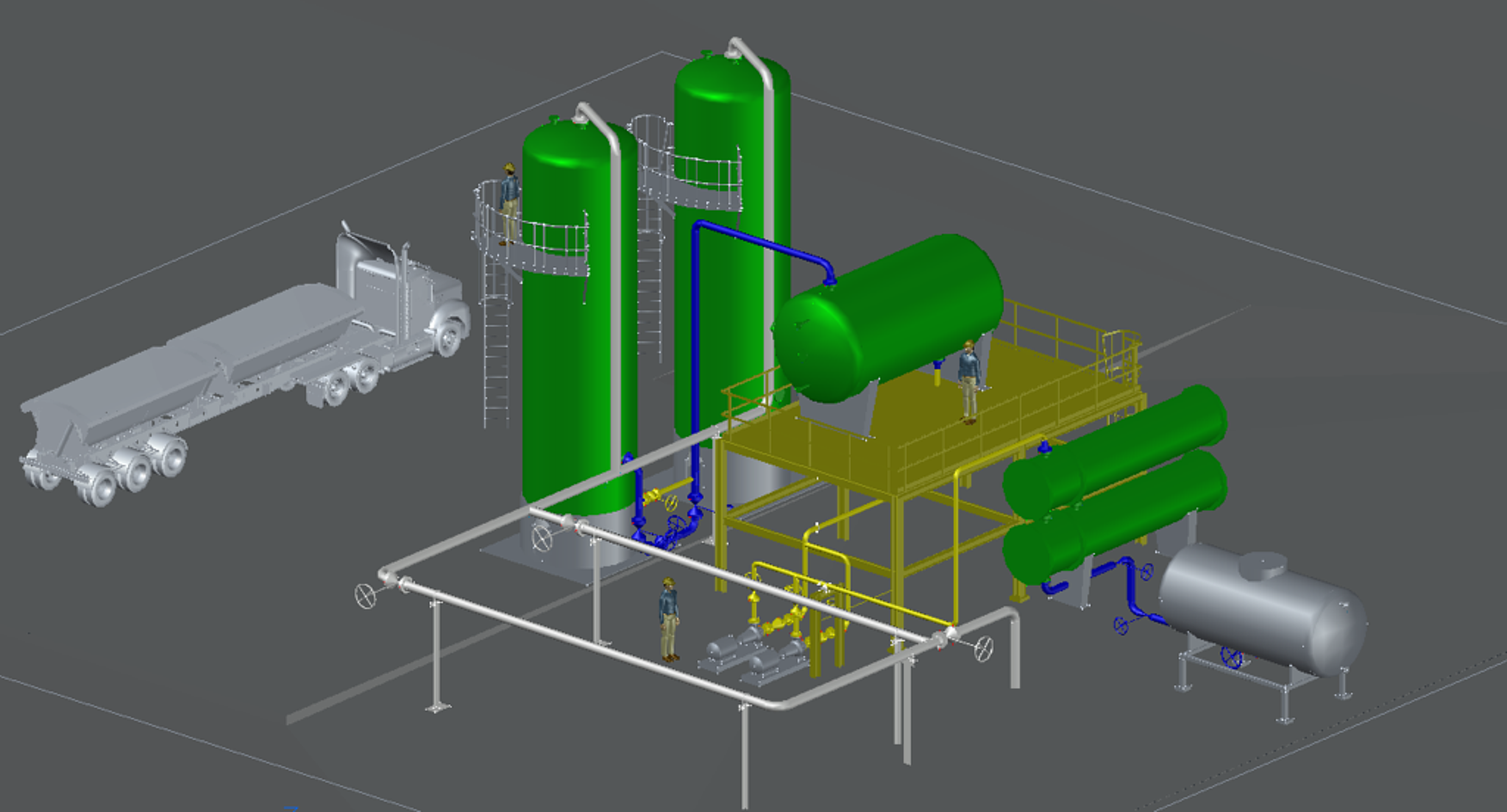

A pressure system contains a fluid or gas under pressure and they support a wide range of processes found in nuclear facilities. Pressure systems can incorporate a wide range of equipment from small air receivers to reactor pressure vessels and primary circuit equipment, which is often subject to very high pressures and temperatures.

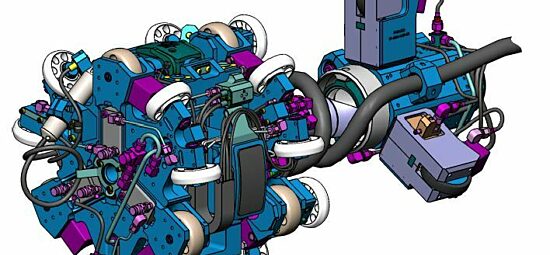

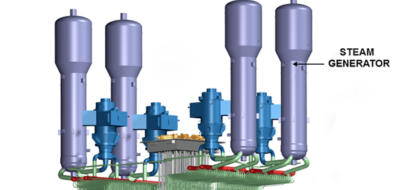

Components that make up the pressure boundary within nuclear facilities, normally include pipes, vessels, heat exchangers/steam generators, pumps and valves. They typically have heightened requirements and separate standards that define both how they are designed and manufactured.

Our work on pressure boundaries and pressurized equipment includes being involved in the development of pressure boundary codes and standards. This gives our subject matter experts detailed and current knowledge, which enables us to design, build, specify and procure, pressure boundary equipment with confidence.

Key Benefits

-

Robust Quality Assurance Program

Our quality assurance program meets the complex requirements that accompany designing, procuring, inspecting, testing and maintaining complex pressure systems used within nuclear facilities. The program is designed to meet the requirements of several quality standards, allowing us to execute work for a wide variety of customers and applications. Our program includes compliance to ISO 9001, CSA B51, CSA N285, CSA N286, CAS N299, 10CFR50 Appendix B, 10CFR21 and ASME NQA-1.

-

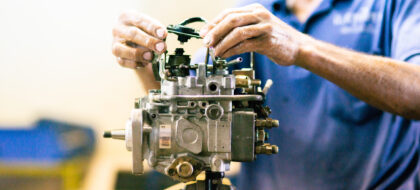

Qualifications and Experience

Our team has several decades of nuclear industry experience, much of it focused around safety, licensing and regulatory affairs. We are often involved with various standards and technical committees. We take pride in maintaining strong involvement in the industry and apply this invaluable experience to your registered or unregistered pressure system.

-

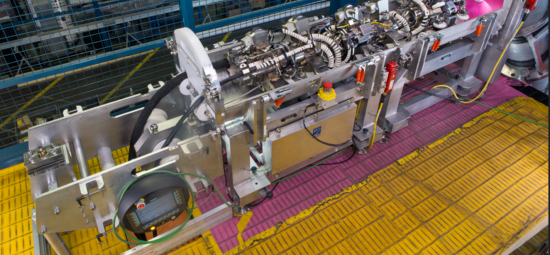

State-of-the-Art Facilities and Equipment

With over 30 laboratories, that span more than 400,000 sq ft globally, we have state-of-the-art equipment to meet your fabrication, assembly, testing and qualification requirements.

Sub Topics

Capabilities