Project Overview

The AP-1000 is a nuclear facility designed and sold by Westinghouse. It is a pressurized water reactor with improved use of passive nuclear safety and many design features intended to lower its capital cost and improve its economics.

The AP-1000 required a number of vital Equipment Qualification (EQ) tests to be performed for qualification.

How We Helped

We were a preferred vendor for Westinghouse’s EQ testing during qualification of the AP-1000. Our existing test system was upgraded to meet the new requirements of this Generation II+ power plant.

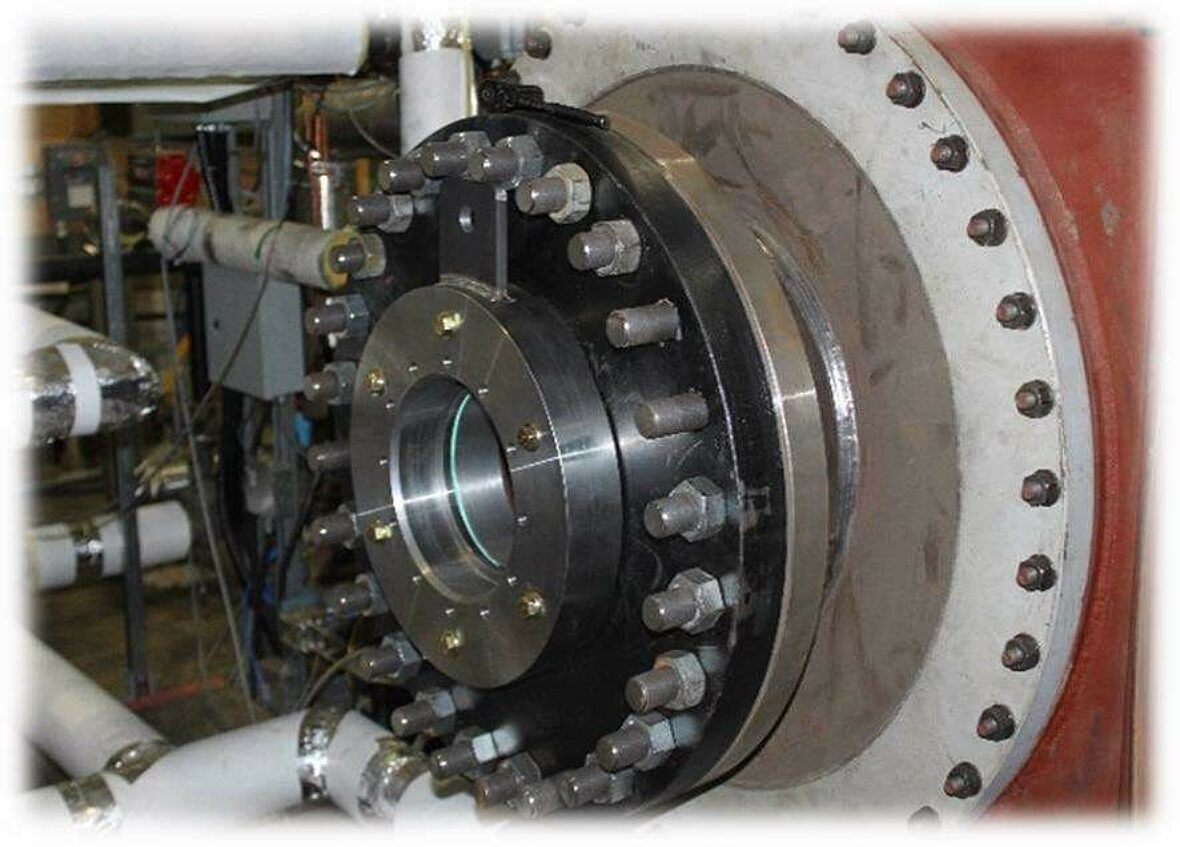

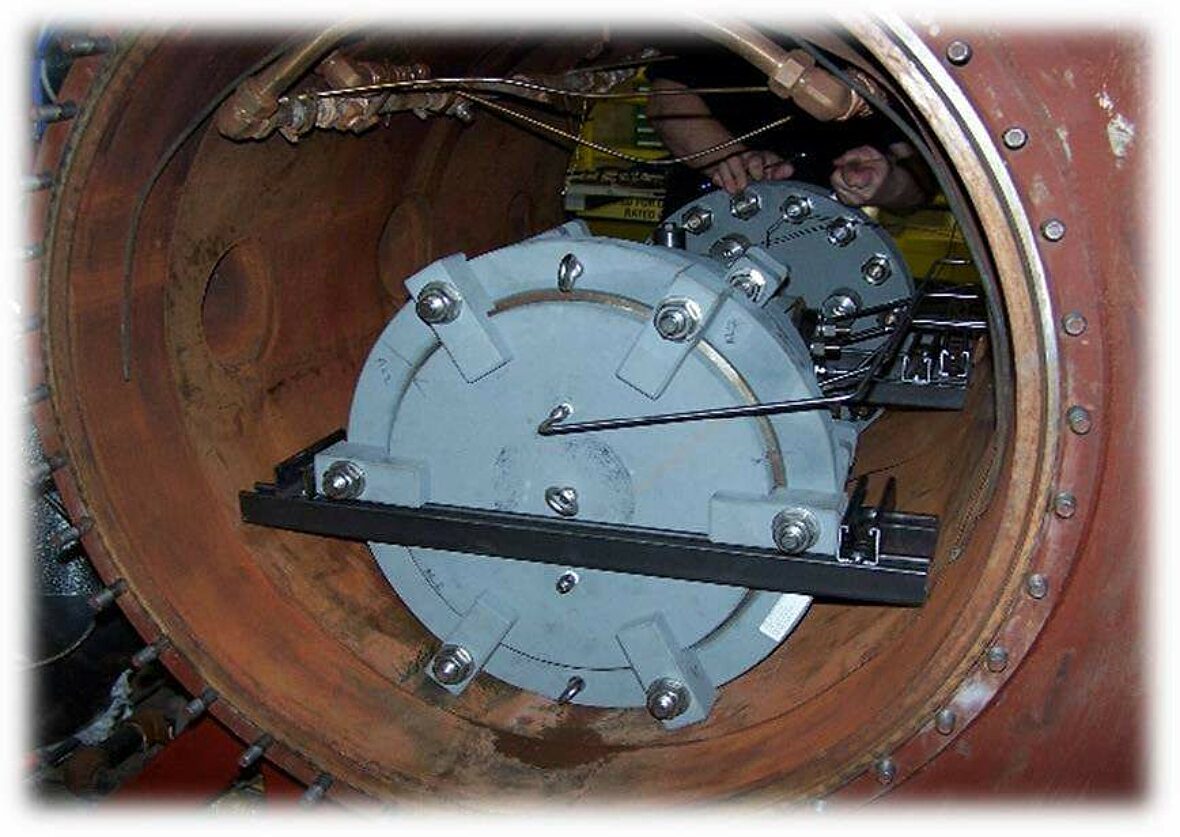

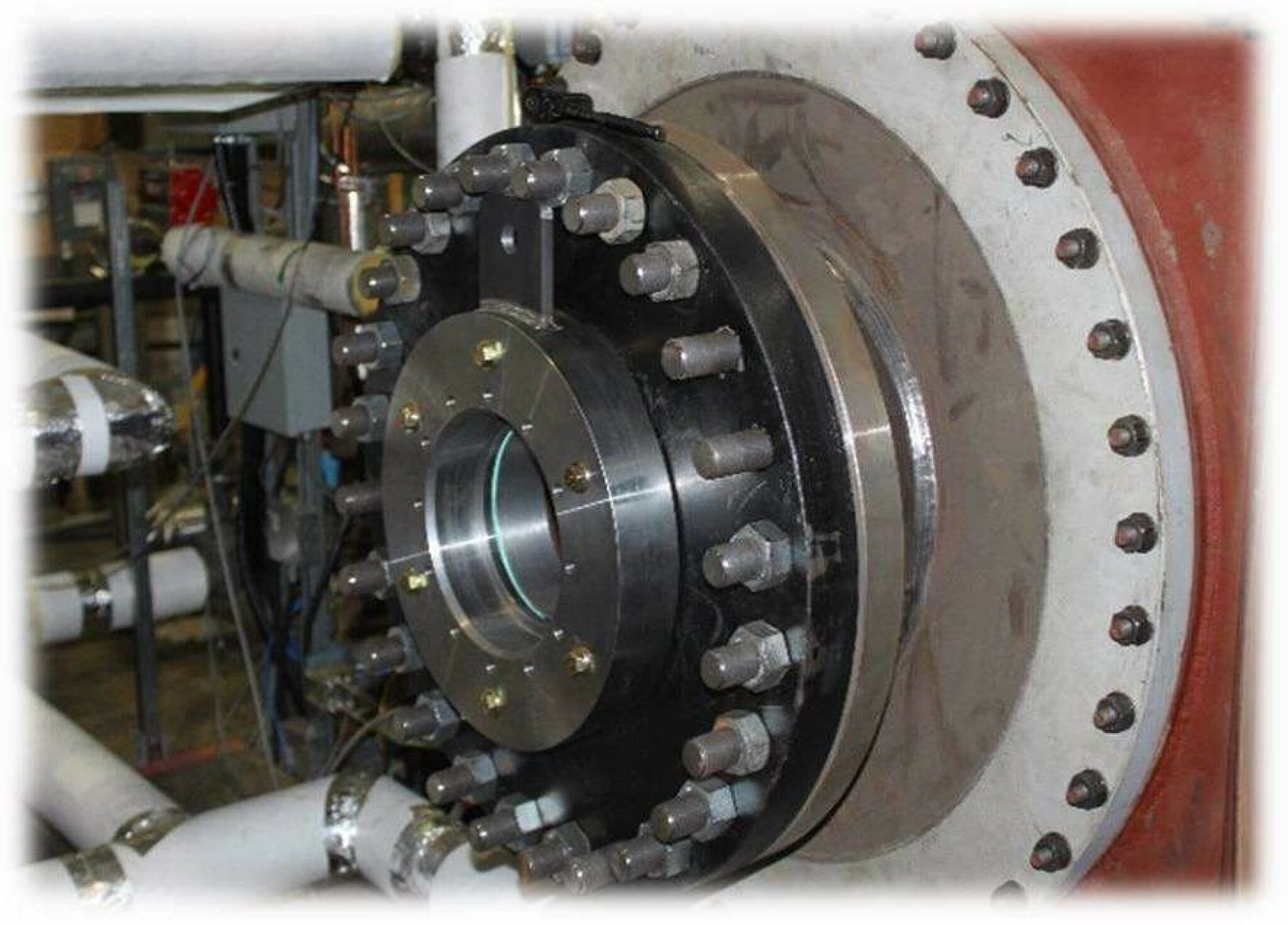

Our staff have direct experience in designing, fabricating and modifying heavy laboratory equipment. Our existing EQ Loop in Toronto was designed in the 1990s and expertly maintained since then. From 2008 to 2010, we upgraded the original test system to meet the new requirements of the Generation II+ AP-1000 power plant designed by Westinghouse. This included adding new components to meet the more severe temperature and pressure conditions for the design. Major upgrades included a new superheater, chemical spray loop and modular test chamber.

In 2020, upgrades were made to the test system to perform testing to severe accident conditions such as those experienced in Fukushima. These EQ system upgrades as well as our decades of EQ lab experience demonstrate that our staff are capable running, fixing, upgrading, and maintaining EQ equipment.

We worked directly with Westinghouse and the manufacturers to qualify components such as airlock doors and equipment hatches, instrumentation and controls, mechanical, electrical and more (polymers, paint, etc).

Qualification

testing was successfully completed in accordance with the test procedure, and

final reports were delivered to the customer within budget and schedule.