Materials & Nuclear Component Testing Overview

Successful engineering of components for use in challenging conditions calls for a detailed understanding of the materials they use and their performance. This is then backed up by testing to confirm design criteria have been met.

We offer a wide range of materials investigations and testing services so that we can provide you with the data you need to be confident in the performance of your material, component, or system. These services support many industries but are most applicable to the nuclear industry and other highly regulated industries.

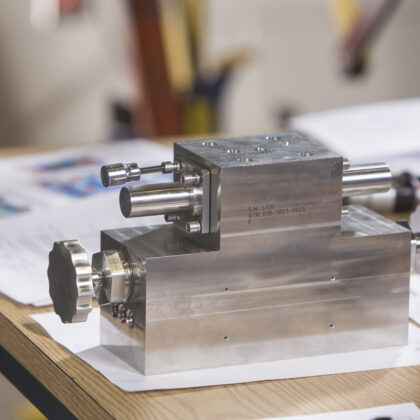

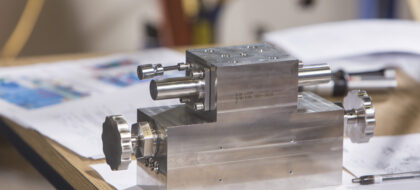

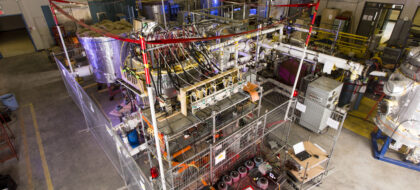

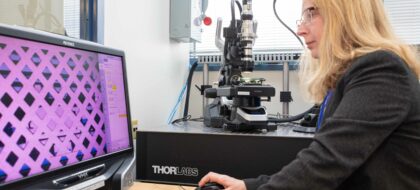

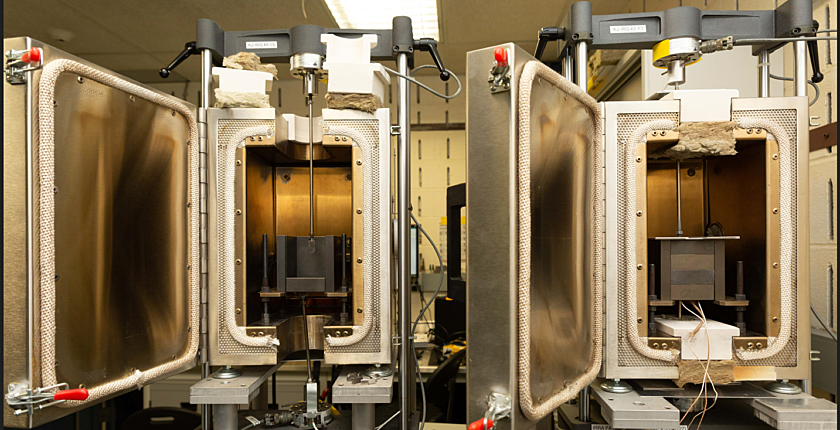

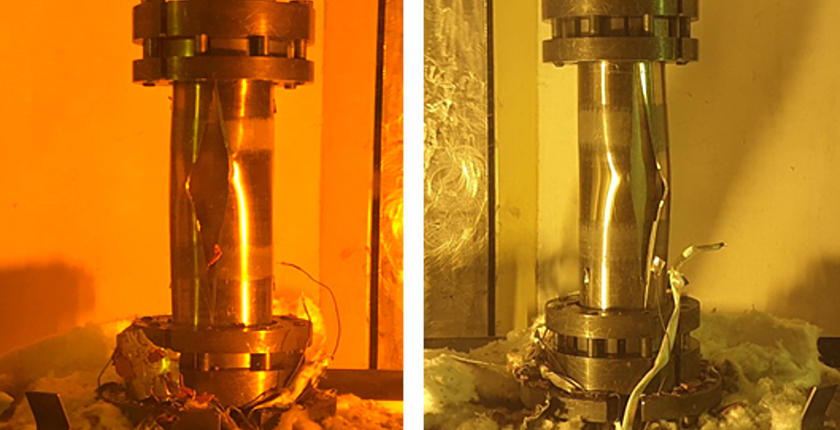

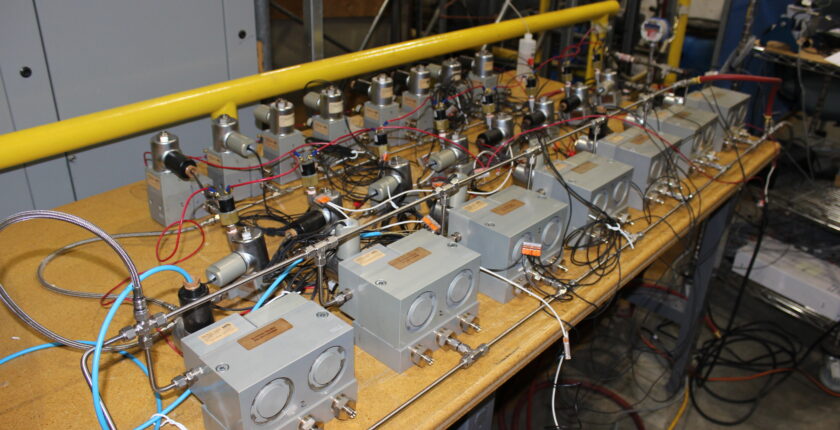

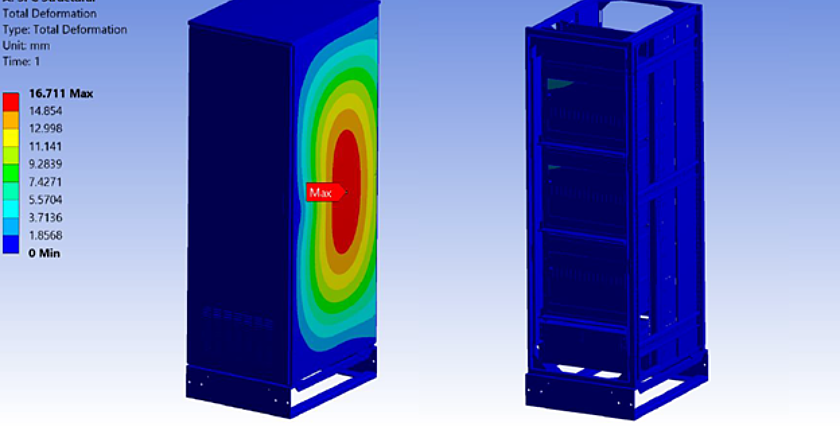

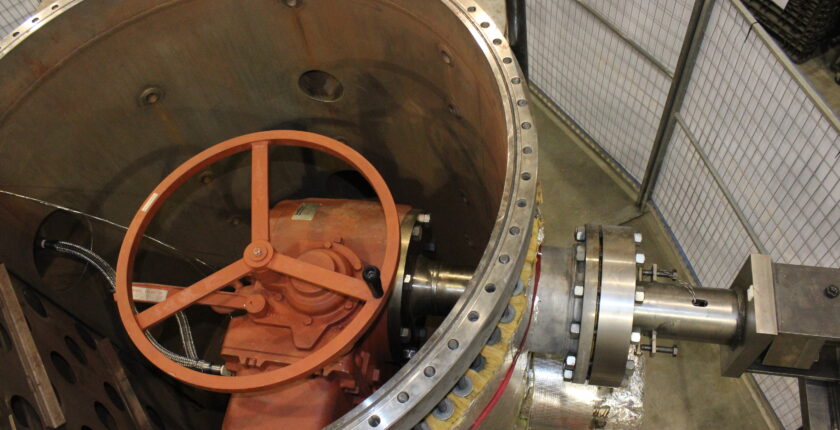

Our services include materials tests, detailed components tests, and forensic analysis. We can imitate earthquakes, establish rates of corrosion, check components in many different environmental conditions and we can even simulate a loss of coolant (LOCA) incident at a nuclear facility. We qualify repair materials for use on structures, systems, and components and qualify off-the-shelf parts for use in nuclear facilities. Our materials experts perform component and materials analysis in both conventional and licensed radioactive laboratories.

We are able to define the problem, plan the test program, and perform the work needed to help you achieve the plant safety and reliability you desire and to prove to your regulator that you are doing it.

Why Our Materials & Nuclear Component Testing?

-

Comprehensive Capabilities

With all our in-house expertise and specialized testing capabilities, we can quickly mobilize the right team of materials experts to understand the challenge and then undertake the work needed to resolve it.

-

Broad Range of Testing Capabilities

Whether you need a component environmentally qualified, a repair material qualified for use, or confirmation of integrity in beyond design basis conditions, our team of technicians and experts can help

-

Radioactive Laboratories

Our fully licensed radioactive laboratory allows us to conduct forensic analysis or tests on activated materials and components

-

Rapid Response Capability

We understand the significance of emergent issues and can deploy our teams on a moments notice to resolve the most urgent challenges.