GridSim Lab High Power Testing Overview

Our GridSim Power Laboratory is an advanced, independent facility purpose-built for full-power testing and certification where test cases can be simulated to provide valuable data for real-grid scenarios. This applies to distributed energy resources (DERs), battery energy storage systems (BESS), power converters, inverters, rectifiers, generators, gensets and traction systems – up to 12 MVA across a wide range of voltages and frequencies.

Our lab helps manufacturers, developers, and utilities accelerate innovation, certify products, and ensure safe renewable power integration worldwide. We are experienced working with Nationally Recognized Testing Laboratories (NRTLs) and certification companies, such as UL Solutions, CSA Group, and Intertek.

We test to leading global standards, including UL 1741 (SA & SB), IEEE 1547.1-2020, UL 9540, CSA C22.2 No. 107.1, IEC 62109, IEEE 1653, and more. Our team provides interoperability testing per IEEE 1547.1-2020, including SunSpec Modbus and IEEE 2030.5. Partner with GridSim to test, certify, and future-proof your technology.

The lab is funded in part by the Ontario Ministry of Energy’s Smart Grid Fund and Alstom.

Why GridSim Lab High Power Testing?

-

High-Power, Flexible Testing

Test renewable generation, inverters, and medium-voltage AC or DC power systems, at full power up to 12 MW, across wide voltage and frequency ranges in this full-service, independent facility.

-

One-Stop, Turnkey Facility

With multiple feeds, grid emulation, and balance-of-system equipment, coupled with on-site high-voltage, high-current, and consultancy services, the GridSim Power lab provides a complete testing solution.

-

Expert Certification Support

Our specialists have extensive expertise in IEEE, UL, CSA, and other global standards to quickly identify, analyze, and resolve issues during type-testing.

-

Faster Time-to-Market

Pre-certified systems reduce field commissioning and on-site compliance testing, helping you save time and costs while meeting modern utility requirements.

GridSim Lab High Power Testing Capabilities

Features

Power Feeds

‑ 4 bidirectional high-power feeds to test floor

‑ Consume power to 12 MW continuous

‑ Circulate power through test objects without load banks

- Authorized to export to local grid

Test Bays

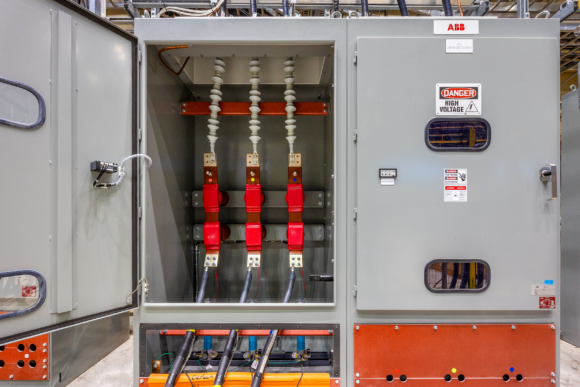

‑ 4,000 ft² test bay with live-voltage interlocks, strong floor & ground grid

‑ Quick-connect panels with high-power cabling stock

Control

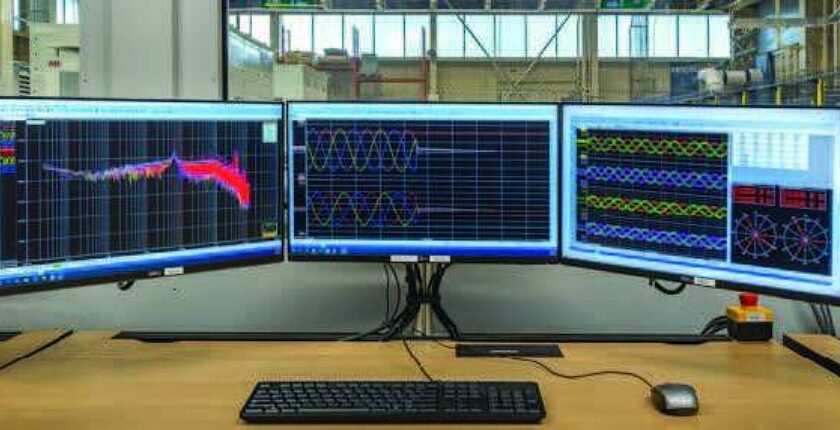

‑ Full phase voltage, angle, and frequency control with fast response

‑ Low harmonic distortion voltage supplies

‑ Full DC voltage and DC current control

‑ Control rooms with dedicated operators

Power Equipment

‑ High power rectifiers, snubbers, capacitors and inductors available

‑ Load banks available (AC / DC resistive, capacitive, inductive)

Ancillary Services

‑ Temperature chambers (Hot & cold environments)

‑ Precision calibrated instrumentation & data logging (Voltage, current, temperature)

‑ Cooling equipment, pumps, fans, fittings

‑ On-site equipment specific subject matter expert support

‑ Access to other on-site labs (High voltage, high current, mechanical, chemistry, rotating machines, seismic)

‑ Field service engineers and technicians available on request

- International cross-border logistics and shipping support

Specifications

Power Feeds & Test Voltages

‑ 60 Hz AC: 12 MVA continuous @ 27.6 kV

‑ Flexible DC: 5 MW continuous, programmable voltage and current control

‑ Flexible AC (45–67 Hz): 10 MVA continuous, programmable individual phase control to 41.4 kV

Grid & Auxiliary Power

‑ Auxiliary power @ 120–600 V

‑ Adjustable source short-circuit strength to 1,000 MVA

Lifting Capacity

‑ 72 ft working height, truck-access doors

‑ 75 ton and 15 ton bridge crane with rigging equipment

What to expect when testing in GridSim Power Lab

Kinectrics provides a full-service testing solution, including:

‑ Test plan development for client approval

‑ Lab setup prepared before equipment arrival

‑ Support for Equipment Under Test (EUT) delivery, installation and commissioning

‑ All test equipment supplied (Client provides only EUT/accessories)

‑ Test execution per plan (Client may operate EUT)

‑ Client and/or third-party witnesses welcome

‑ Data recording with daily reports

‑ Final report with raw data provided

‑ EUT disconnection and preparation for shipment

Our Proven Experience

Quality Assurance & Technical Standards

- CSA C22.2 No. 107.1

- Power conversion equipment

- IEC 62109

- Safety of power converters for use in photovoltaic power systems

- IEEE 1547.1

- IEEE Standard Conformance Test Procedures for Equipment Interconnecting Distributed Energy Resources with Electric Power Systems and Associated Interfaces

- IEEE 1653.2

- Uncontrolled Traction Power Rectifiers for Substation Applications up to 1500 V DC Nominal Output

- ISO 9001

- Quality Management System

- ISO 17025

- Testing & Calibration Laboratories

- UL 1741

- Inverters, Converters, Controllers and Interconnection System Equipment for Use With Distributed Energy Resources

- UL 9540

- Energy Storage Systems and Equipment – Battery Energy Storage Systems (BESS)