Stations & Underground Cables Overview

Electricity networks have been leaders in asset management for decades. Many have detailed asset management plans in place that are continuously being improved and refined. Historically, networks have had a high degree of redundancy and surplus capacity in their circuits so that cable failures have not necessarily led to network failures or outages. Station and underground cables have often been out of sight and mind, and despite their importance, they have largely been forgotten and do not have detailed asset management plans.

Moving towards a net-zero carbon economy, electricity networks will have increasing demands placed on them, including higher loads, and changing load profiles. As a result, they will need to offer greater flexibility and focus on controlling costs. In this context, proactive planning, measurement, and management of cable assets are increasingly important.

Our holistic cable offering helps you achieve the lowest cost of ownership for your cable assets with services that are relevant throughout the cable lifecycle including engineering design and consulting, cable manufacturing support, installation support, operation and maintenance services, and end-of-life or life extension solutions. The information we can provide on your cable system enables you to make risk-based decisions with a true understanding of your assets and the options available.

Why Our Stations & Underground Cables?

-

Understand Your Options

We provide you with the best data enabling you to make risk-based decisions with a complete understanding of your assets.

-

Independent Unbiased View

Third-party testing, in compliance with industry standards, ensures you get an unbiased, independent view of the state of your assets.

-

Cutting-Edge Solutions

Our ongoing research and development program keeps us at the cutting-edge and enables us to help you with your product development.

-

Complete Lifecycle

Our cable lifecycle management services support all stages of the cable lifecycle.

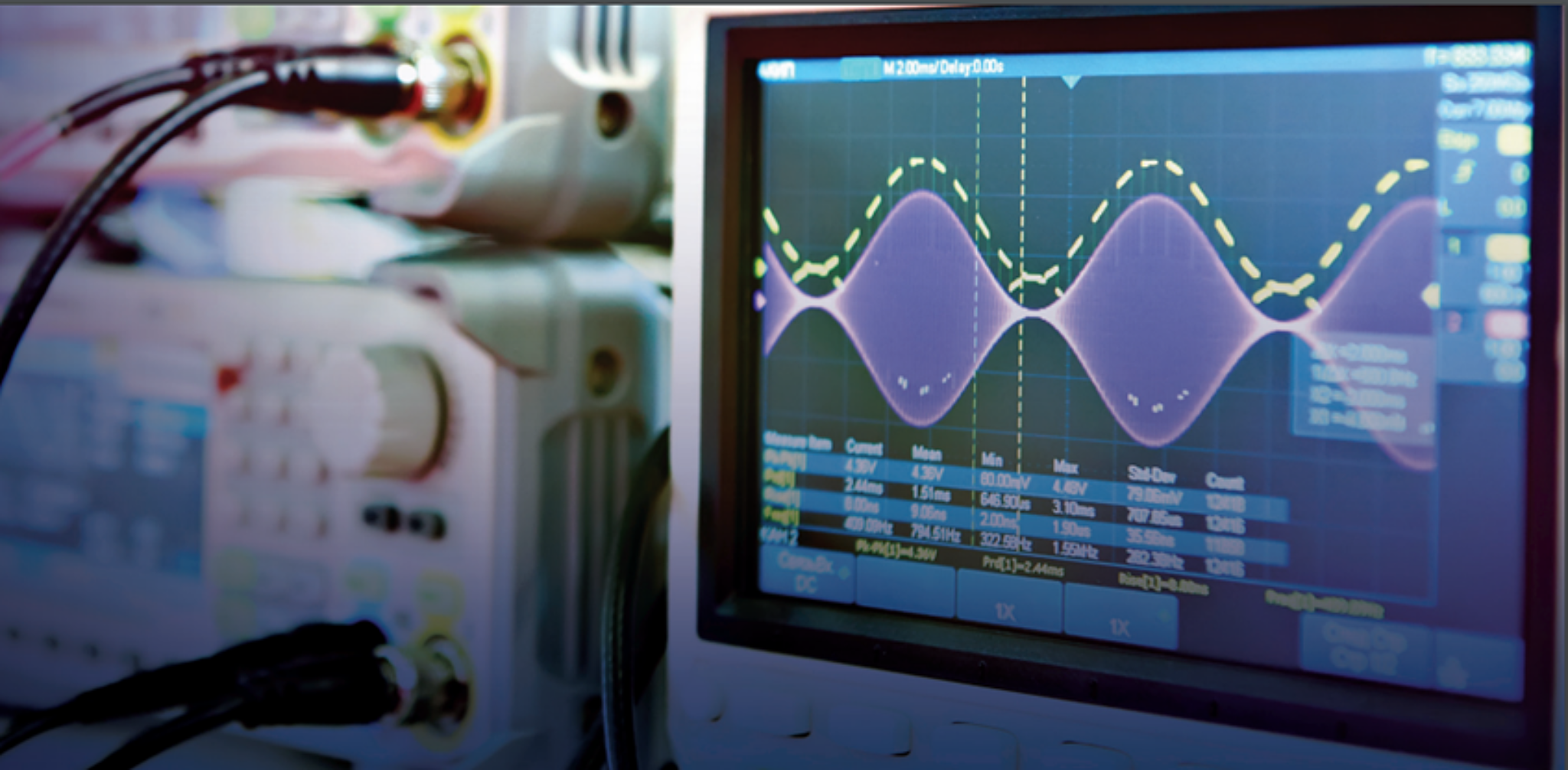

Our Stations & Underground Cables Technical Abilities

Comprehensive Equipment & Expertise

- Our involvement in new product development keeps us up to date on new technologies and applications

- We have our own fleet of Resonant Test Systems (RTS) allowing us to provide longer and higher voltage cable testing rapidly around the world

- Research and development for industry organizations allows us to remain cutting-edge

- Our team includes materials scientists with proven track records of designing and testing materials for electrical applications

- We are technically unbiased and provide independent testing consistent with industry practices

- Renowned technical experts and engineers with a large suite of mobile test equipment

- Our state-of-the-art labs contain extensive equipment, that offer a one-stop shop for your cable testing

In-Field & Lab Testing

In-Field:

- High Voltage In-Field Commissioning Testing

- Post Repair Testing

- Maintenance Testing

- Visual Corona Testing

- Radio Interference Voltage (RIV) Testing

- Partial Discharge Testing

- Independent Expert Witness

- Tangent Delta

- LIRA

- Dielectric Spectroscopy

Lab:

- Contamination – Solid Layer, Clean Fog Method

- Visual Corona Testing

- Radio Interference Voltage (RIV) Testing

- Partial Discharge Testing

- Wet and Dry Power Frequency Withstand and Flashover Testing

- Dry Lightning Impulse Critical Flashover and Withstand Testing

- Steep Front Impulse Voltage Testing

- Materials Testing

- Tangent Delta

- Qualification Testing

- Independent Expert Witness

Our Proven Experience

Quality Assurance & Technical Standards

- AEIC Standards

- Technical Specifications for Cables

- ANSI Standards

- Technology Standards by the American National Standards Institute

- ANSI/ICEA S 108-720 HV/EHV

- Standard for Extruded Insulation Power Cables

- ANSI/ICEA S-97-682 and 94-649 MV

- Standard for Utility Shielded Power Cables and Concentric Neutral Cables

- CEA Standards

- Technical Standards and Regulations for the Power Sector Published by The Consumer Electronics Association

- ICEA Standards

- Cable Standards for Electric Power, Control and Telecommunications Industries

- IEC Standards

- International standards for all electrical, electronic and related technologies

- IEEE 48

- IEEE Standard for Test Procedures and Requirements for Alternating-Current Cable Terminations Used on Shielded Cables Having Laminated Insulation Rated 2.5 kV through 765 kV or Extruded Insulation Rated 2.5 kV through 500 kV

- IEEE 386

- IEEE Standard for Separable Insulated Connector Systems for Power Distribution Systems Rated 2.5 kV through 35 kV

- IEEE 404

- IEEE Standard for Extruded and Laminated Dielectric Shielded Cable Joints Rated 2.5 kV to 500 kV

- IEEE Standards

- Standards developed and maintained by Institute of Electrical and Electronics Engineers

- NEMA Standards

- Standards Used in North America for Various Grades of Electrical Enclosures

- SCT36 Testing

- Site Commissioning Tests - Cable Systems

- UL Standards

- Standards for Product Safety