Stress Analysis Overview

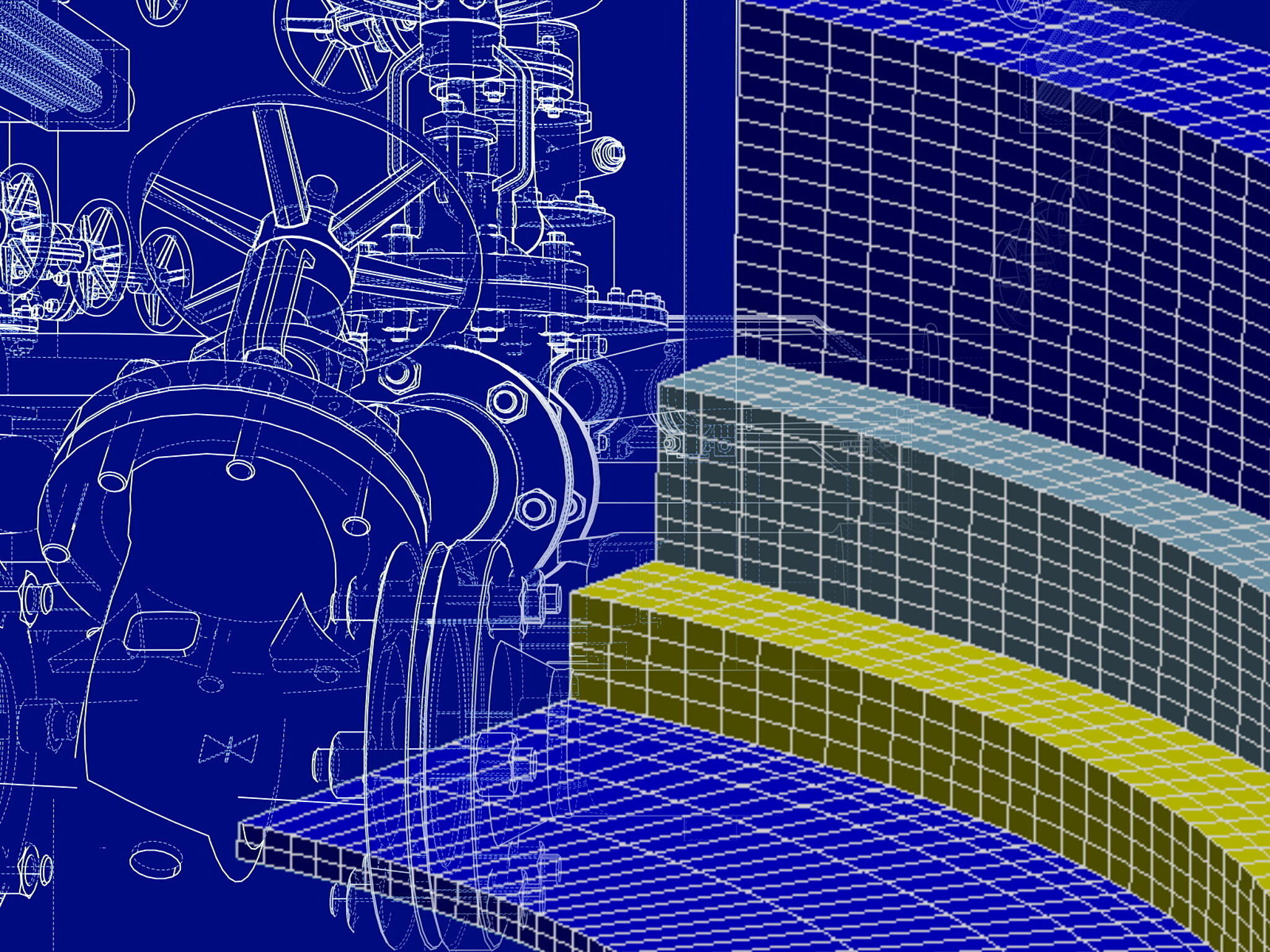

Elaborate piping systems, common in thermal power plants, create complex loading conditions that include thermal gradients, pressure transients, water hammer, and seismic forces. Stress analysis describes the range of techniques used by engineers to calculate and model stress and strain to determine the reaction of a structure or component to external loading.

Stress analysis is now often undertaken with sophisticated computer-aided simulation tools, normally based on the finite element method, that allow stress concentrations to be quickly identified. This work is often supported by classical mathematical techniques and modeling and it is an essential component of most engineering design work.

We go beyond computer modeling to offer a personal, customized, service that provides the best engineering solution for the application. Our team has experience analyzing stresses, strains and deflections in structures, systems and components. The results from the analysis are compared against design code allowable limits, which are intended to guard against all potential failure modes. Our modeling is made efficient by an experienced team that includes industry-recognized experts who are developing the latest nuclear and industrial design standards and who have years of operational experience.

Why Our Stress Analysis?

-

Related Disciplines

With subject matter experts specializing in all related subjects, including materials science, seismic analysis, heat and fluid flow, modeling, and much more, you will always get a top-class accurate analysis.

-

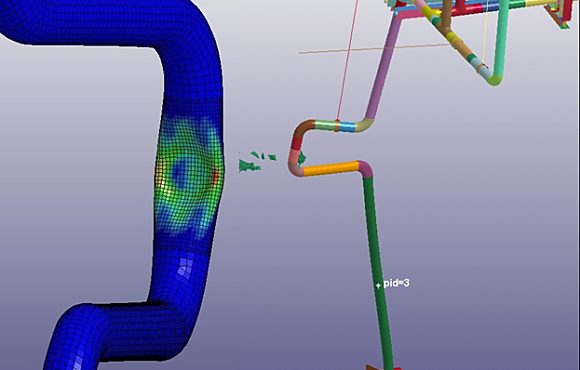

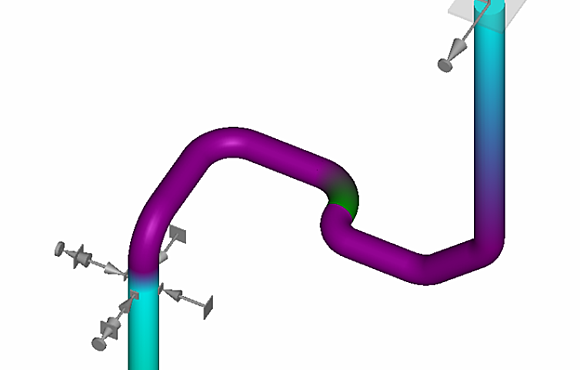

Complete Piping System Analysis

Assessments and analysis of water hammer, vibration, seismic, pressure, and thermal transients for piping systems, including buried piping, bolts, flanges, and supports, to inform all your piping analysis needs.

-

Data Acquisition

Where stress analysis is being undertaken to support the justification of ongoing operation or to design for a retrofit, we will come to your site and acquire data and design details to enable us to offer a complete service.

-

In-House Testing Capability

Our capability to test materials and designs in-house allows us to acquire data and confirm results through experimentation to add further certainty and accuracy to the analysis.

Our Stress Analysis Technical Abilities

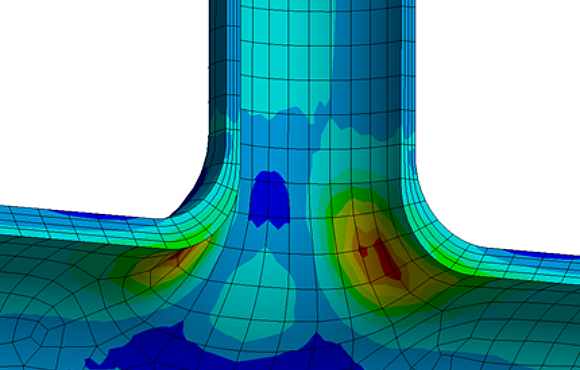

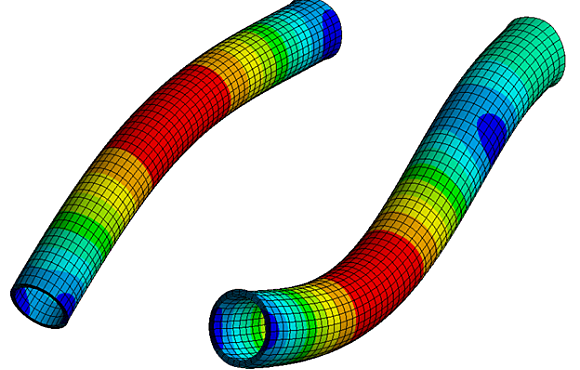

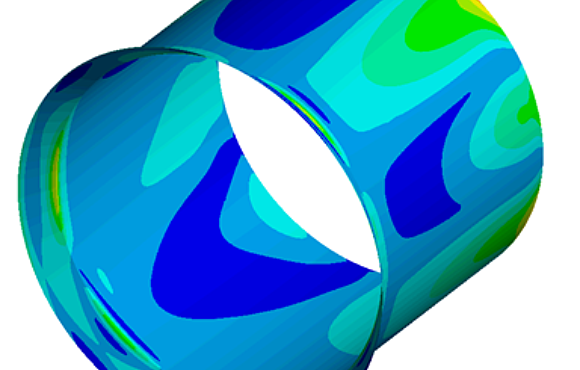

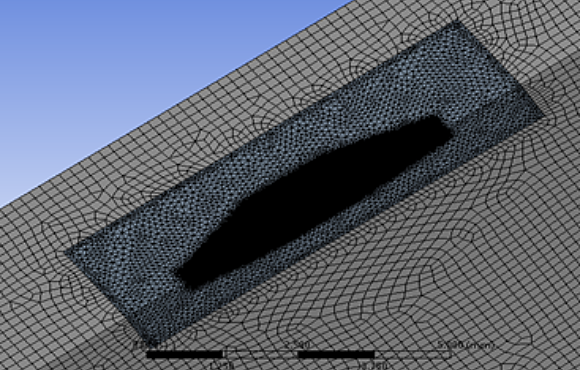

Finite Element Analysis

We simulate physical effects to determine precise limitations.

- Component and Tooling Design-by-Analysis and Qualification (Vessels, Fittings, Valves, Inspection Tools, etc.)

- Linear Elastic Analysis including Thermo-Structural Response Under Steady-State and Transient Thermal Loads

- Nonlinear Structural Analysis Including Material Nonlinearity (Limit Load Analysis, Ratcheting, etc.), Geometric Nonlinearity (Buckling, Large Deformation, etc.), Element Nonlinearity (Contact, Friction, etc.), and Non-Linear Finite Element Analysis

- Dynamic Analysis including Modal & Harmonic Analysis, Pipe Whip, Thermal Stratification, Drop Test Simulation, Plane Crash, Accident Simulation, Self-Weight, Cladding, and Weather Simulation (Wind, Snow, Tornado Impact etc.)

- Vibration Analysis including High Cycle Fatigue and Fluid Structure Interaction

- Applied Loads including Dead, Imposed, Live, Normal, Upset, Emergency, Fault and Hazard Loads (each with different levels of acceptability).

Piping Analysis

We do assessments of the flow and stresses involved in piping and we analyze the capabilities and limitations.

- Prescribed Loading Including Water Hammer Analysis, Vibration, Seismic, Pressure, and Thermal Transients

- Design Support including Buried Piping, Weld Calculations, Bolt & Flange Analysis, Valve Replacements, and Pipe Support Assessments

- Assessment of New and Existing Piping Systems to Several Available Code Revisions of ASME Boiler and Pressure Vessel Code (BPVC) or ASME B31.1

We also investigate stresses arising from:

- Dead-Weight, Thermal Expansion, Cold-Pull, Wind and Snow Loading, and Dynamic Effects

Fitness-For-Service Assessments

We determine how appropriate it is for components to remain in service based on their measured condition and foreseeable maintenance requirements.

- Assessment of Adequacy of Existing Components to Remain in Operation for Plant Life Extension After Refurbishment

- Assessment of Flaws in Components such as Heat Exchanger Local Wall Thinning and Expansion Joint Structural Integrity

- Inverse Code Assessments for Existing Components

Our Proven Experience

Quality Assurance & Technical Standards

- API 579-1/ASME FFS-1 (2021)

- Fitness-For-Service Evaluation

- ASME B31.1

- Power Piping

- ASME BPVC

- Boiler and Pressure Vessel Code

- CSA N285.0-17/N285.6 Series-17 (2017)

- General Requirements for Pressure-Retaining Systems and Components in CANDU Nuclear Power Plants/ Material Standards for Reactor Components for CANDU Nuclear Power Plants

- CSA N289 Series (2022)

- Requirements for seismic design and qualification of nuclear power plants

Key Clients

Projects

Based on personal knowledge, I attest to the expertise and capabilities of Kinectrics' Stress Analysis team to handle routine (no job is too small) to the most challenging first-of-a-kind complex (no analysis we cannot handle) stress analysis problem using state-of-the art technology and tools respecting the clients’ urgent schedule and budget requirements.