Project Overview

The Isotope Production System (IPS) is an innovative partnership between Kinectrics, Bruce Power, Isogen (a Kinectrics and Framatome Company) and the Saugeen Ojibway Nation, which revolutionizes the supply of medical isotopes. It has greatly advanced the global medical community's fight against cancer.

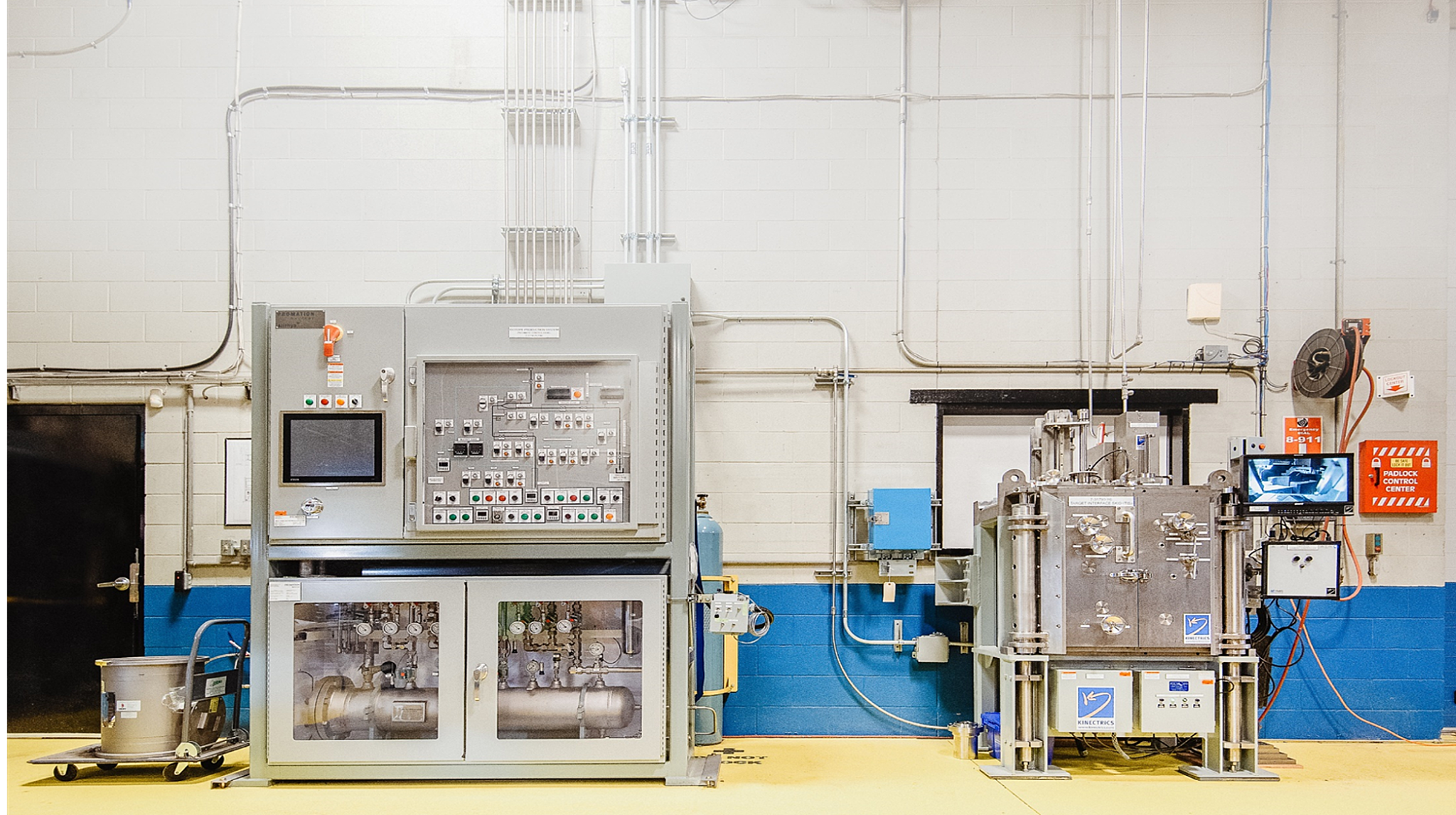

The IPS is designed to produce lutetium-177 in a CANDU reactor through neutron capture of ytterbium-176, the target material. This project fulfills the irradiation portion of the supply chain by using Bruce Power reactors to generate Lu-177. Bruce Power harvests the isotopes from the reactor core, packages, and turns over the items to a transporter. The transporter then ships to an isotope processor who purifies the radioactive isotope according to Good Manufacturing Practices, to produce a pharmaceutical grade material.

The integration of this system at Bruce Power was a critical step forward that has provided the needed large-scale production capacity in the medical isotope supply chain. demonstrating for the first time that short-lived medical isotopes can be produced on a commercial power reactor.

How We Helped

We successfully lead and completed the engineering, procurement, and commissioning of this project, and worked with our partners to commission the system on-site at Bruce Power.

The scope of this project was divided into the following three main segments:

Engineering

This support included the generation of all documents and drawings required to develop the detailed design of the system. Activities included completion of a walkdown on-site to verify design and assembly considerations, preparation of all design documents, fabrication drawings, and bills of materials needed for procurement and Commissioning, production of design manuals and on-site assembly instructions, a human factors and FMEA analysis. Support was also provided for licensing and registration activities (CNSC, TSSA, etc.), and all design support needed during the procurement and Commissioning phases of the project.

Procurement

This phase of the project required working with many specialized suppliers to ensure high-quality and on-time delivery of all items required for Commissioning. Activities included sourcing specialized vendors for commercial off the shelf components, custom fabricated parts, and specialty material such as tungsten, issuing purchase orders to all suppliers specified in the bills of material, providing vendor oversight through source surveillance and incoming inspections to confirm critical characteristics, and review and approval of special processes such as painting, welding and NDE by Kinectrics subject matter experts.

Commissioning

This effort included the provision of a full-time site-based Commissioning lead to oversee the assembly of the system at Kinectrics to verify critical parameters prior to delivery on-site. This required the preparation of all Field Change Notices, providing all required design input needed throughout the Commissioning phase, and shipping the items to site for commissioning.

Our successful execution and delivery of this project has cemented Bruce Power’s place on the world stage as a global leader in medical isotope production.