Nuclear Services Overview

There is significant pressure placed on nuclear facilities to produce power safely and efficiently, with high capacity factors, however, there are occasions when power production has to stop to undertake outages. Whether they are planned or unplanned outages, there timely and effective execution is essential to safely restarting station operations to generate power as quickly as possible.

Planned outages arise from a need to refuel (when online refueling is not possible), carry out essential inspections or replace an aging component. Planned outages are meticulously planned, components are procured and tested in advance, and outage activities are often rehearsed on mock-ups. With a lot of work being undertaken simultaneously, everything needs to be properly scheduled and precisely choreographed. Unplanned outages require rapid identification of the cause and a quick disposition of issues to allow for quick and flexible support.

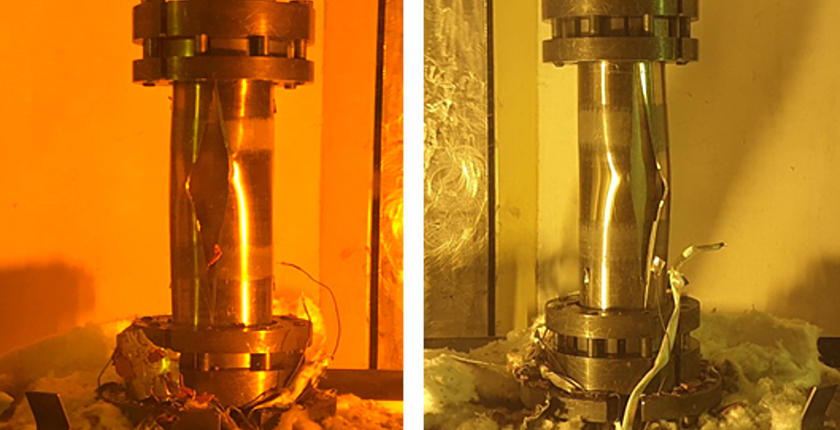

Our team can support you in all aspects of your site operations and outages, providing the essential nuclear services needed. In addition, we develop, build and maintain specialized equipment we then deploy without impact to critical path during outages. Lastly, we have a variety of facilities we utilize to analyze materials to obtain crucial data for our subject matter experts to review and provide advice. This includes our extensive forensic capability to identifying the cause of emergent issues and provide solutions.

While we support all aspects of a plant’s lifecycle, many of the things we do can be linked back to operations and outages. A summary of the services we offer to directly support nuclear outages and site operations are identified in the sections below.

Why Us?

-

Specialized Inspections

We take on the most challenging nuclear inspections. Our extensive array of custom tooling enables us to tackle even the most specialized inspection tasks. There are also times when emergent issues arise, that require us to develop, build, and test specialized tools to get the job done safely and reliably.

-

Well Planned & Responsive

The secret to a successful outage lies in detailed planning, but sometimes the unexpected can occur. We meticulously plan, prepare, and rehearse to ensure minimal disruption and critical path adherence while simultaneously maintaining the flexibility to respond quickly to emergent issues.

-

Experienced & Diverse Team

Our outage and site support services draw on our diverse array of specialized capabilities in areas of design and engineering, safety and licensing, and lifecycle and project management.

-

Services Designed for You

By working closely with you we develop an understanding of your needs, operating practices, and of the way your station functions, so our services can be customized to fit seamlessly into your outage activities.

Our Nuclear Services & Technical Abilities

Our Proven Experience

Key Clients

Projects

BRIMS Maintenance & Execution Program

Custom Circumferential Wet Scrape Tool (CWEST) Design & Supply