Machining & Prototyping Overview

At our in-house precision machining and prototyping facility, we utilize a range of techniques and state-of-the-art machines to produce high-precision parts that meet the highest quality standards.

Our advanced machining services team utilizes specialized equipment such as CNC machines, wire-and-sink electrical discharge machines, 3D printers, and modeling/manufacturing software to ensure correct programming and design compliances.

We offer rapid prototyping, batch machining, irradiated component repair – and we undertake larger production runs of custom items.

Why Our Machining & Prototyping Services?

-

Fast Turnaround

With a lot of experience to call upon, we can quickly establish the optimum production approach and develop the production process so that we can accommodate challenging production schedules. 3D printing is adding to our rapid response capability.

-

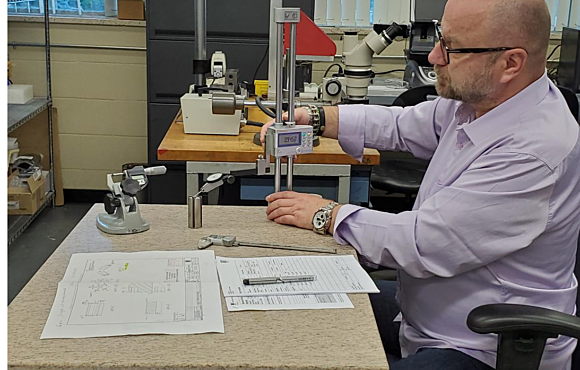

Careful Inspection

Critical characteristics are established and used in the inspection of machined parts. Calibrated tools and machines, including coordinate measuring machines (CMM), are utilized prior to ensure that every part meets its technical specification.

-

Specialized Materials

Specialized equipment and experience enable us to fabricate using materials that are difficult to machine such as zirconium, tungsten, nitronic, and titanium.

-

Repairs of Irradiated Components

Our licensed facilities enable us to safely undertake the repair and maintenance of components that may be activated and/or contaminated.

-

Quality Assured Components

The qualifications, processes, inspections, reviews, and acceptance levels for all machining processes are prescribed by our quality assurance (QA) program, ensuring quality requirements are documented and adhered to throughout the machining process.

-

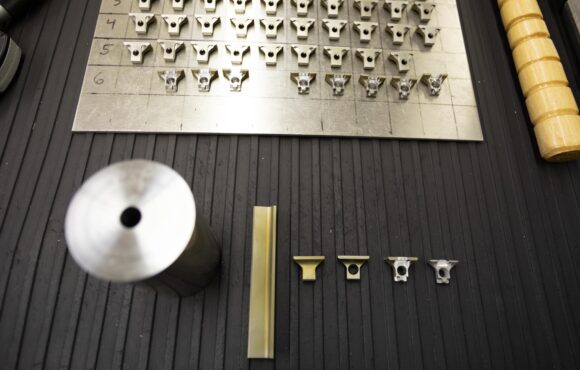

High Precision Machining

We provide parts with zero defects to a high degree of precision by using our CNC and Electrical Discharge Machining (EDM) equipment. We are able to complete the micro-machining of metallurgical samples down to 1 micron.

Our Machining & Prototyping Technical Abilities

Advanced In-House Machining and Prototyping Services

The capabilities of our advanced machine shop includes:

- 5-Axis CNC Machining. Used to enhance part accuracy and increase production efficiency

- Wire and Sink Electric Discharge Machining (EDM). Supports fabrication of complex shapes and allows for use of challenging materials

- Laser Etching. Provides part customization in the form of unique logos and serial numbers

- 3D Printing. Aids in rapid prototyping and design generation

- Coordinate Measuring Machine Measurements. Tool used for inspection of parts and verifying part acceptability

- Computer Aided Design (CAD) and Manufacturing Software. Required for CNC machines, supports prototype and design development, and aids in the calculation of machining cycle times

Our Proven Experience

Quality Assurance & Technical Standards

- 10CFR50 Appendix B (2021)

- Quality Assurance Criteria for Nuclear Power Plants and Fuel Reprocessing Plants

- CSA N285 Series

- General Requirements for Pressure-retaining Systems, Components, and Supports in CANDU Nuclear Power Plants

- CSA N299

- Quality assurance program requirements for the supply of items and services for nuclear power plants

- CSA Z299

- Nuclear Quality Assurance Program

- ISO 9001

- Quality Management System